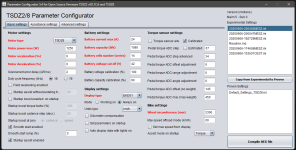

Compared to other TSDZ8 motors, it looks like:Hello, I'm from Germany and I flashed my TSDZ8 motor and 860c display with the following firmware:

osf_tsdz8_860c_v00_01_19.hex

860c_v13-v20.1c.5-1-860c-bootloader.bin

Can someone explain to me how to correctly set up or calibrate the torque sensor?

With my settings, I'm getting too high human wattage readings.

I also can't get the thumb throttle to work.

Thanks in advance.

Translated via Google Translate

- torque ADC offset is quite hight (other users reported a value arounds 160/190)

- torque ADC max is quite low (other users reported a value around 450).

Still I do not have a lot of feedback from users about their values. So it could be that your values are correct.

In torque ADC step, you entered 93. I expect this is the result of the calculation done by 860C.

In fact I think that this calculation is not valid anymore for OSF TSDZ8. I expect it is based on the raw values provided by the torque sensor and filled in 860C. In OSF for TSDZ8, the raw values from torque sensor are remapped in order that the range between offset and max is 160 (what is the expected range of TSDZ2 motor).

To get more realistic value for human power, try reducing the torque ADC step. Sorry but at this stage, I can't say which value to use (probably between 30 and 65). Note: I expect that when you change this value, you would also have to change the different values of assistance for the modes where human power is used in the calculation if you want to keep the same feeling.